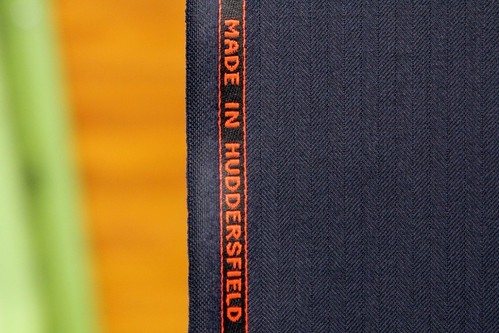

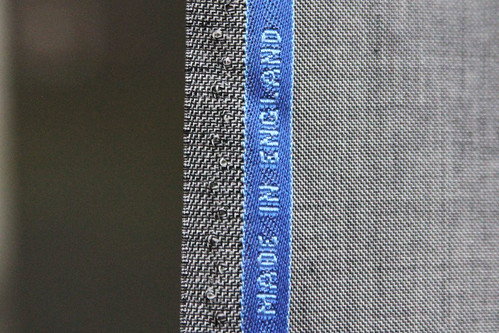

"I get a great rush from seeing someone in the street wearing a garment made from our cloth and I can actually tell this almost straight away," explains Bulmer and Lumb's Edward Waterhouse. Fine worsted cloth, and its reputation for excellent quality and fine designing is renowned the world over and for a erudite eye like Waterhouse's, it captures the attention. "Textile manufacturing excites me personally due to increased demand from UK retailers and designers to source cloth from the UK again. It is extremely encouraging that brand such as Alfred Dunhill, Richard James and Burberry are looking to source made in England cloth." As the curtain raises once again on London Collections: Men and especially on The English Gentleman at Lord's with The Woolmark Company and blog favourite Lou Dalton, the great rush experienced will become more familiar in its frequency. After a whistle stop tour of West Yorkshire that saw me explore their homes in Bradford and Huddersfield, I'm beginning to feel the rush too.

"Being based in two places in West Yorkshire and employing 70 people in Huddersfield and 130 in Bradford we have a close link with local communities. There is family atmosphere within the company and we have had several generations from the same family working for the Bulmer and Lumb Group, this ranges from a Dye Operative to a Combing Operative to a Weaving Technician.

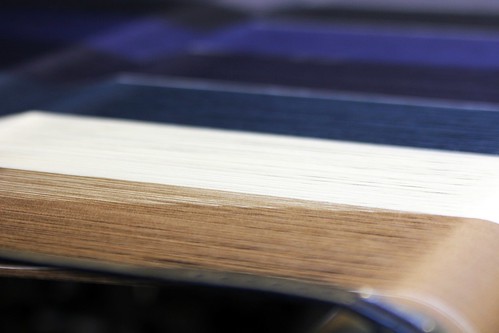

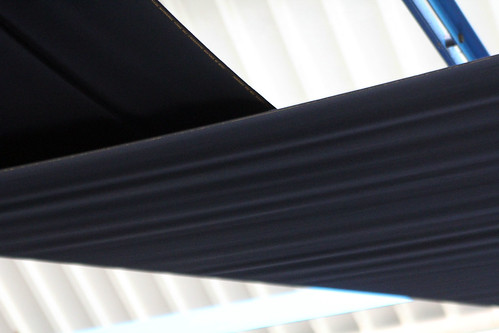

Today, the Bulmer and Lumb Group produce a wide range of fabrics, ranging from its luxury fine worsteds to worsted fabrics worn by the military. Bulmer and Lumb’s history is as a dyer, with expansion into fabric production in 2001 and then in 2005 with the addition of Taylor and Lodge. Now, the group has the ability to sell finished fabric but actually we also sell raw wool top, dyed wool top, space dyed yarn, package dyed yarn, top dyed yarn along the various manufacturing stages of producing fabric."

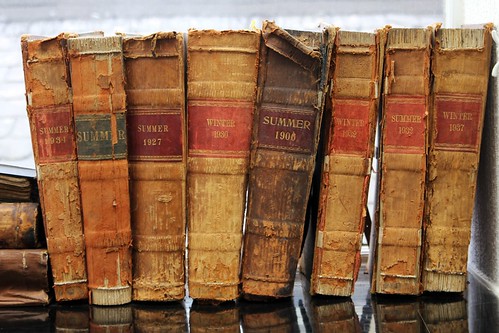

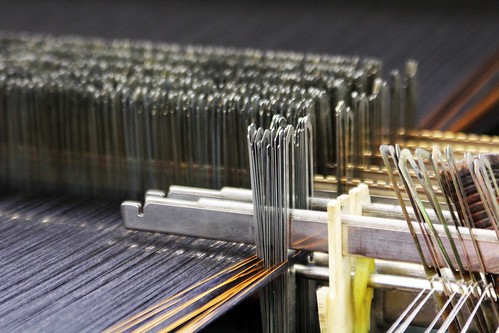

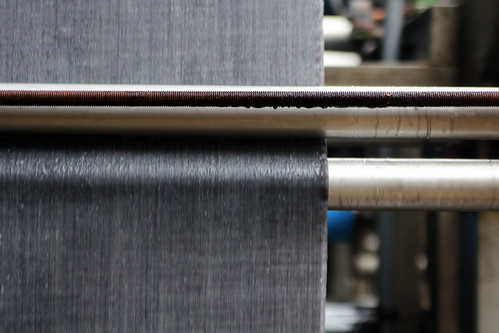

Weaving an intricate and dazzling group, Bulmer and Lumb Group is ever evolving, helping to drive the textile industry forward. For the last eight years the group has owned the world renowned Taylor and Lodge in Huddersfield. Reputations do not come about by chance. The fame Taylor and Lodge enjoys is built on over a century of experience and a deep appreciation for the methods and skills that go towards producing a superior product. The company has occupied its Rashcliffe Mills factory in Huddersfield, on the edge of the Yorkshire Moors, since its founding in 1883. Craftsmanship and well honed skills are essential to the product and it was a pleasure to be able to watch it all unfold in a space that has seen the same processes come together for centuries.

As I walked through and looked on at each process of construction, the balance between old and proven techniques and machinery from various eras since the industrial revolution, really left a lasting impression on me.

Through its careful selection and control of raw materials together with continual investment in the latest equipment, Bulmer and Lumb continue to push textile manufacturing to new heights. These elements ensure that the production processes are amongst the most efficient and balanced in the industry and provide all the essential elements for growth. Edward Waterhouse explains.

"Due to the fact that Bulmer and Lumb dyes its own raw material we are the world leaders in supplying Uniform fabrics, which have mix and match shade repeatability. We can guarantee that a fabric made from a top dyed yarn is the same shade from the 1stmetre to 100,000th metre. This then also lends itself to producing fine worsteds for suiting’s made by Taylor and Lodge, we use yarn from our own range but supplement them with yarn bought in to make a highly sort after fabric collection. With our skilled and experienced design team we can offer individuality to our customers on a made to order basis, differing from the uniform business which is primarily stock based.

Bulmer and Lumb will keep evolving to meet the tough demands of our customers. The blend we offer of our knowledgeable and experienced staff and up to date machinery, I feel we are well placed to increase our sales globally with the sales to new markets important. A point that I must stress is that due to the fact we dye in the UK, we have to adhere to a very strict code of practice of which many around the world will not have to."